News Story

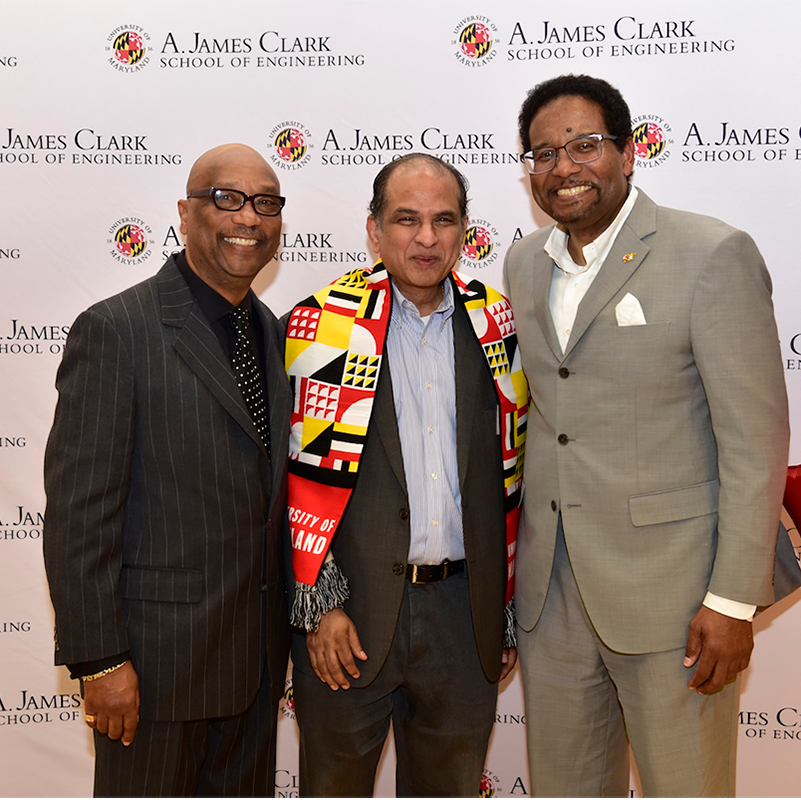

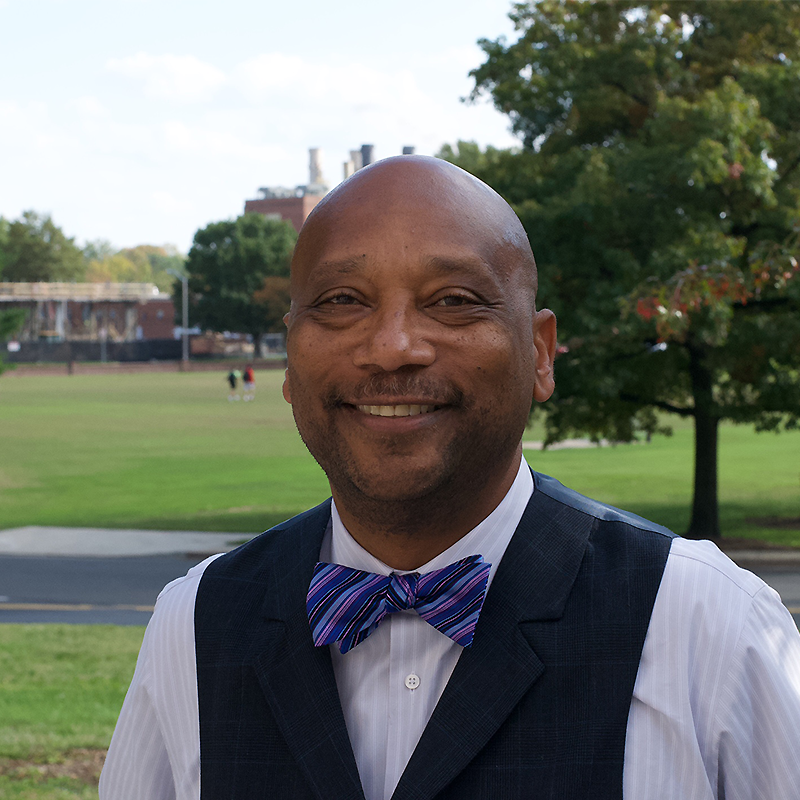

Eddie Elburn Recieves Steve Adamson Memorial Award

For the past year, Eddie has served as the president of the University of Maryland’s IMAPS Student Chapter. He organized and led local chapter events, including guest presentations and poster competitions. He fostered collaboration the IMAPS Chesapeake Chapter and helped reinvigorate an interest in IMAPS at the University of Maryland—adding 20 new members during his term as president.

During his time at CALCE, Eddie completed work on evaluating the reliability of semiconductor components, analyzing the information available for electronic parts, and numerous lab service projects. He served as a teaching assistant for undergraduate-level courses and led study sessions to help his students succeed. Eddie is currently working to complete and defend his thesis, “Utilization of Data and Models for Commercial off the Shelf (COTS) Reliability Assessment,” and has begun working as a Power Tools Reliability Engineer with Stanley Black and Decker.

Abstract

The use of commercial off the shelf (COTS) parts in space or military applications has been restricted by the perception that the COTS parts do not match the reliability of higher-grade parts. There is also an assumption that the information needed to assess reliability is not available for COTS parts. To evaluate the truth to these perceptions, the information required for a reliability assessment of electronic parts, COTS or not, was catalogued based on failure mechanisms. This article provides a detailed analysis of what types of part level information is available for COTS parts from manufacturers and other external sources. Since temperature is one of the most common stress parameters in common failure mechanisms, a quantitative metric has been developed based on the thermal information availability for a part factoring in temperature ratings, qualifying rating location on the part, thermal resistance, power dissipation, and other factors. A methodology has been developed to account for uncertainty due to incomplete thermal information in reliability estimations. Methodologies have also been developed for modeling actual application conditions using sensor information, and approximating unknown part information with other features of the device such as node size. A case study analysis of 22 COTS parts was completed to evaluate the metric and report on trends in thermal information for several types of parts and manufacturers.

Published September 13, 2018