News Story

Building a Better, Eco-Friendlier Straw

Convenient as they are, plastic straws pose great harm to the environment. More than half a billion straws are consumed daily in the United States alone, going directly into the trash after a single use. Most recycling machines can’t recycle them in any case, due to their shape and size.

So far, efforts at a solution have foundered. Eco-friendly substitutes have proven costly and ineffective, and their poor biodegradability makes them only a slight improvement over the plastic variety.

Now, a team of researchers at the University of Maryland’s materials science engineering and mechanical engineering departments, part of the A. James Clark School of Engineering, have published a paper that details a new approach—one that makes use of the residue, known as bagasse, that is left over after juice is extracted from sugarcane. The paper recently appeared in Advanced Functional Materials.

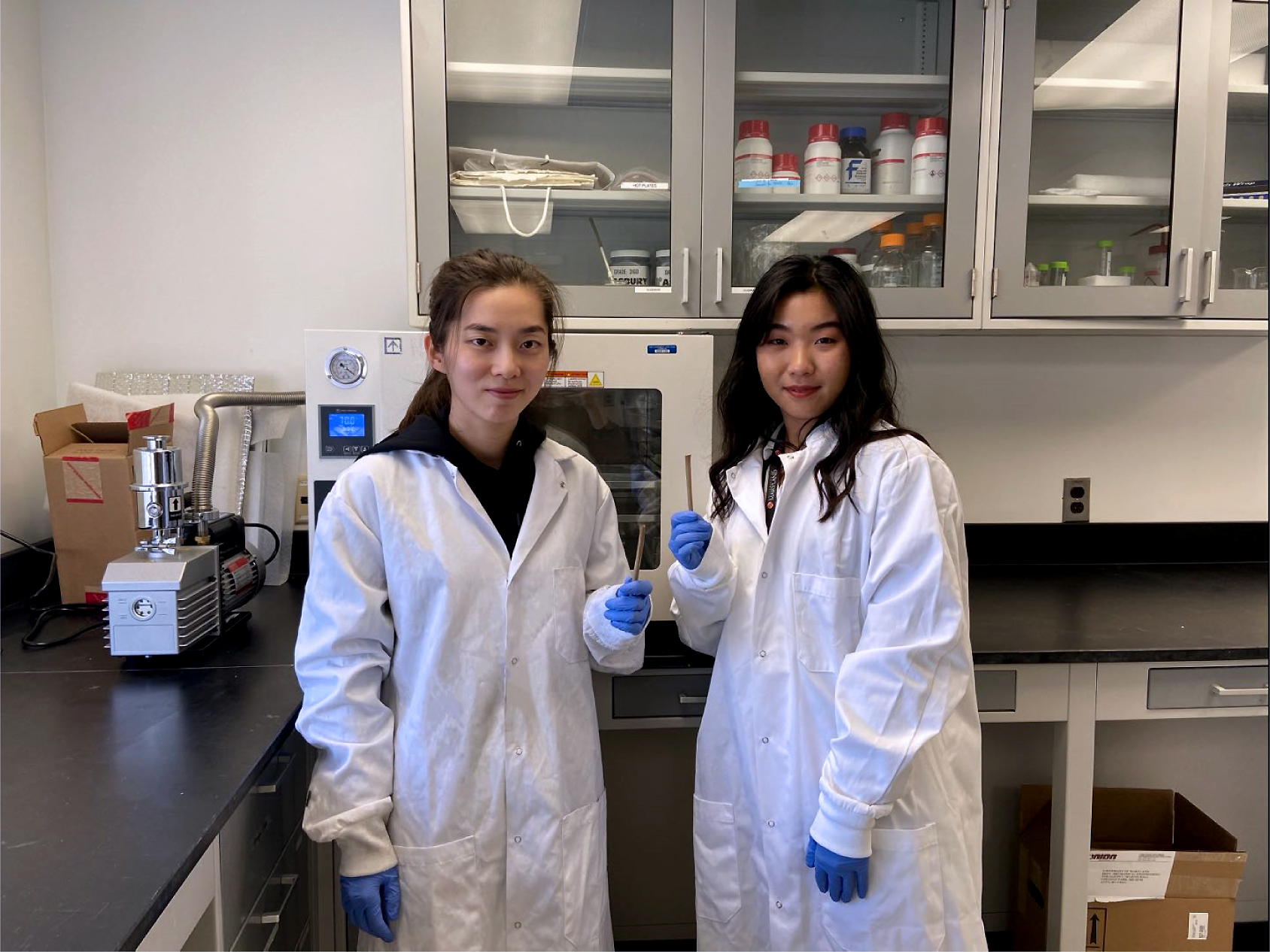

“We have designed all-natural, biodegradable straws by hybridizing nanofibers and microfibers from bagasse,” said UMD postdoctoral student Xizheng Wang, co-lead author of the new paper “This approach provides a promising alternative to petroleum-derived plastic straws.”

“We have designed all-natural, biodegradable straws by hybridizing nanofibers and microfibers from bagasse,” said UMD postdoctoral student Xizheng Wang, co-lead author of the new paper “This approach provides a promising alternative to petroleum-derived plastic straws.”

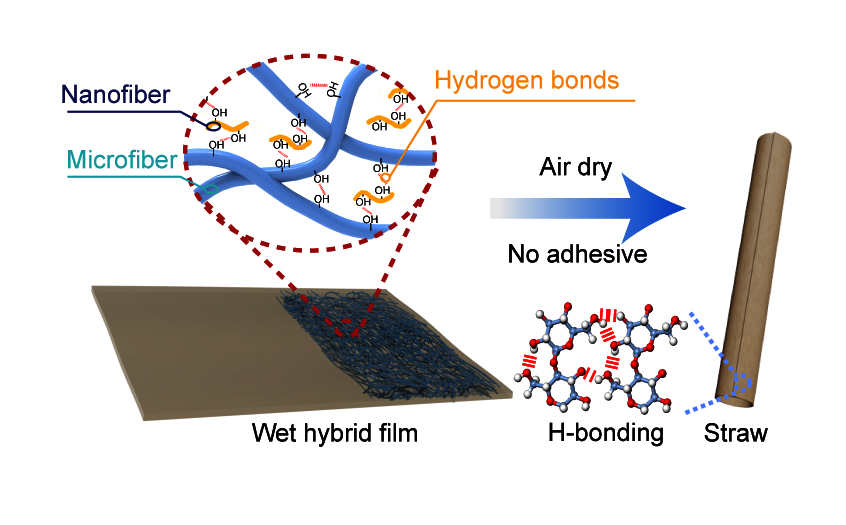

Working under the guidance of Keystone Professor of Mechanical Engineering professor Teng Li and Liangbing Hu, Minta Martin Professor of Materials Science and Engineering, the researchers found that a wet film could be made from the hybridized fibers, then rolled into shape. When the film dries, it naturally seals as a result of hydrogen bonding among the fibers, without the need for a binder.

Straws produced using this method are strong and durable, conduct water effectively, and degrade naturally after disposal. They are also inexpensive to make, since bagasse is a waste byproduct of the sugar industry and can be obtained for little cost, Wang said.

As part of their research, the team conducted extensive modeling and simulations designed to assess the properties of hybridized micro and nanofibers. According to Zhenqian Pang, co-lead author of the paper, the results clearly demonstrate the benefits of hybridization.

As part of their research, the team conducted extensive modeling and simulations designed to assess the properties of hybridized micro and nanofibers. According to Zhenqian Pang, co-lead author of the paper, the results clearly demonstrate the benefits of hybridization.

“We found that cellulose nanofiber has the highest level of strength and cellulose microfiber the lowest but the results are opposite with regard to failure displacement,” he said. “When we calculated the mechanical properties of hybrid fibers, we found they inherit the advantages of both.”

In addition to Wang and Pang, the paper’s authors include Chaoji Chen, Qingxin Xia, Yubing Zhou, Shuangshuang Jing, Ruiliu Wang, Upamanyu Ray, Wentao Gan, Claire Li, Gegu Chen, and Bob Foster, as well as faculty mentors Li and Hu. The team is now working to refine the new straw design.

“We are making progress in improving the stability of our straws in water and reducing the material cost,” Li said. “Both factors are crucial to the success of these straws as a commercial product in the future.”

Published April 29, 2020