News Story

Exaggerated gait allows limbless R2G2 robot to move quickly in confined spaces, rough terrain

Above: R2G2 moves on a concrete surface. Below: The robot can travel up inclines, here on a narrow track barely wider than R2G2 itself.

Roboticists have long known that this kind of "limbless locomotion" is a highly effective way for a robot to move through cluttered and confined spaces. But like snakes, robots that employ rectilinear gaits are slow. They also have a problem maintaining traction on steep slopes.

University of Maryland Mechanical Engineering Ph.D. student James Hopkins has been trying hard to overcome the speed limitations of engineered limbless locomotion. In a robot called "R2G2" (Robot with Rectilinear Gait for Ground operations), he decided to dramatically exaggerate the gait to increase the speed.

"Our current R2G2 model has a maximum forward velocity of one mile per hour, bringing it close to human walking speed," says Hopkins. "Our goal is to develop a gait and a mechanical architecture that will enable high-speed limbless locomotion to support applications such as search and rescue."

"To the best of our knowledge, this is the fastest limbless robot in its class in the open literature," says Hopkins' faculty advisor, Professor S.K. Gupta (ME/ISR).

R2G2 could get faster. "In this design, the speed is linearly proportional to the length of the robot. So by doubling the length we should be able to easily achieve the speed of two miles per hour," Gupta says. To get much above that speed, R2G2 will need an upgrade to more powerful motors.

R2G2 can more through spaces that are problems for other kinds of robots. It can crawl through pipes, and traverse tricky surfaces like grass and gravel. What's more, "it can climb steep, narrow inclines," Hopkins says.

Hopkins used actively actuated friction pads near the head and tail of the robot to improve its traction, and has found that different terrains require unique kinds of friction pads—a bed of nails for traveling over grass; rubber for carpets.

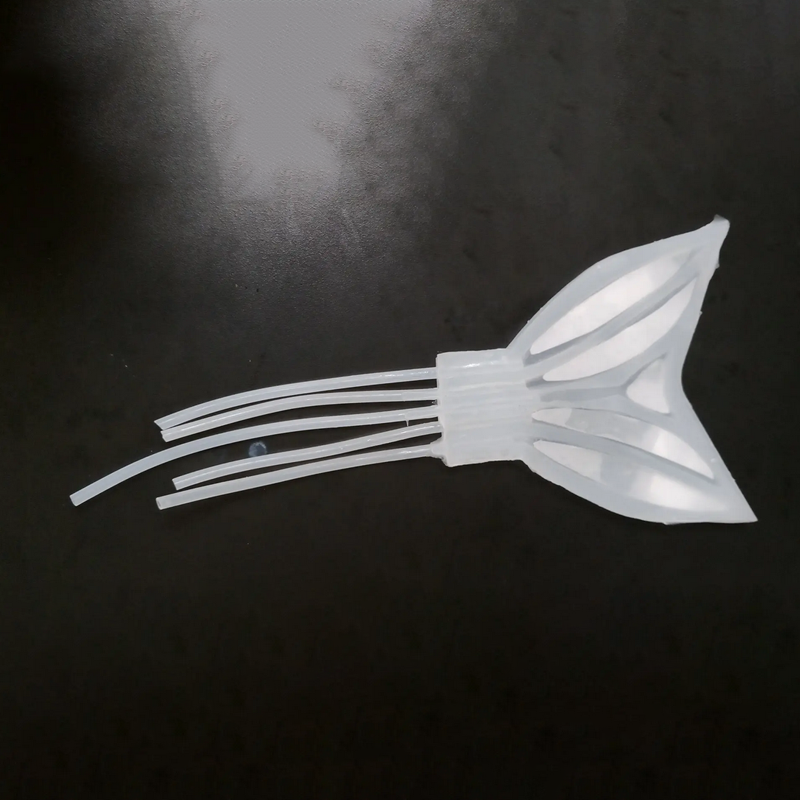

In addition, Gupta and Hopkins used 3D printing technology to create a novel mechanism for expanding and contracting R2G2's body while maintaining a small body cross section. This enabled them to make geometrically complex parts and greatly simplify the assembly of the robot. Other researchers with access to 3D printing will be able to easily replicate R2G2 in their labs.

Currently robots that use limbless locomotion do not come close to their natural counterparts in terms of capabilities. "Unfortunately, we do not yet have access to engineered actuators that can match the natural muscles found in biological creatures," Gupta says, "or highly distributed, fault-tolerant, self-calibrating, multi-modal sensors and materials with highly direction-dependent friction properties. So our design options for limbless locomotion are limited and truly mimicking nature is simply not possible right now."

In the short term, Gupta believes robotics engineers are better off "taking a different approach that exploits inspiration from biological creatures." Robots like R2G2 advance the science because they "take a useful feature in nature and exploit it to the fullest extent."

This research is supported in part by the National Science Foundation.

| S.K. Gupta's blog post about R2G2 | R2G2 YouTube video |

Published October 15, 2013