News Story

In Race With Virus, Researchers Speed Development of Medical Equipment

An engineer creates a molded respirator mask with the help of 3D printing. Photo: Stephanie S. Cordle

With new designs as well as innovative techniques for reviving old gear, University of Maryland faculty and staff are racing to meet dire needs for high-priority medical equipment as the number of COVID-19 cases rises nationwide.

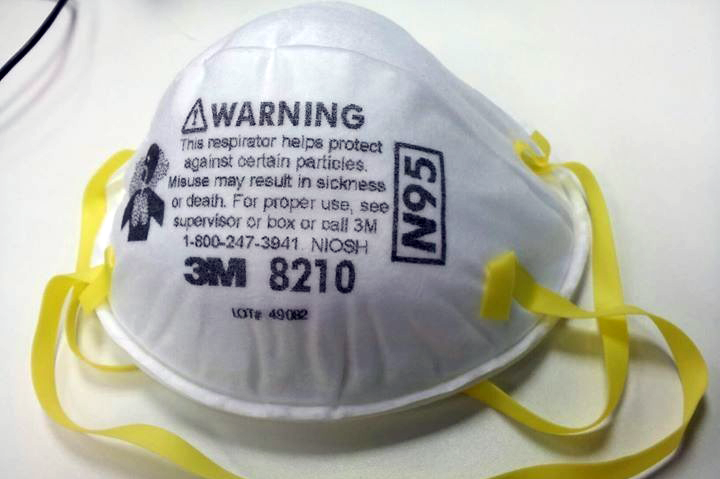

The news has been overflowing with heartbreaking stories of endangered doctors and nurses coddling single, used N95 respirators through multiple shifts, as well as urgent requests from hospitals and public officials for machines to help the sickest patients breathe as an expected wave of COVID-19 cases looms.

In response, researchers in the Robert E. Fischell Institute for Biomedical Devices have zeroed in on several advances that could fundamentally impact the U.S. response to the virus. They goal, they say, is to begin providing new solutions within days, a warp-speed deviation from the normal pace of medical equipment development. Among the top priorities:

- Semi-permanent alternatives to disposable (and now-scarce) N95 respirator masks, created using 3D printing;

- A method to safely sterilize used N95 masks for reuse;

- Simple, cheap, and fast-to-build manual ventilators to augment the nation’s insufficient supply of hospital-grade models.

“There is an outpouring of people trying to figure out ways to help,” said Professor William Bentley, director of the Fischell Institute. “Some of the groups have very proactive, near-term response activities, and others are more far-reaching.”

One group of researchers has developed a method to quickly create customized respirators for medical workers. Unlike N95 masks—filtered respirators meant to be used once and thrown away—their alternative design can use a variety of replaceable filters. At the end of the day, instead of trashing it, users can simply wash it with soap and fit a new filter.

“It has a better seal than an N95 mask, because it is custom fit for each individual,” said Kevin Aroom, engineer in the Fischell Institute. “The other advantage is if there’s a shortage of one kind of filter, you can use another, because it’s designed with a universal flange adaptable to a number of different filter sources, whether they’re commercial or you’re building your own filter material like Peter Kofinas is doing.”

Aroom said the A. James Clark School of Engineering has already supplied a number of masks to doctors and nurses for testing; after further adjustments, he expects to ramp up greater production in Terrapin Works 3D printing facilities on campus next week to supply some area hospitals. A commercial partner soon could take over the manufacturing and begin manufacturing the masks in the thousands, he said.

To create the custom masks, doctors take 3D scans of their faces with portable scanners. The scans provide measurements as a series of points used to create the correct fit.

Clark School researchers and students are working to counter the COVID-19 pandemic in a variety of ways. Learn more at clark.covid.umd.edu.

“You have to go through that fit test to make sure they’re actually sealing,” said Rick Blanton, director of technical operations at the Clark School. “By custom fabricating these to each of the individuals, we automatically can be sure that it’s going to work every single time.”

From the initial scan to manufacturing, they can be ready overnight, and offer other advantages as well, the researchers said.

“It’s neat that the mask itself is clear,” said Jim Zahniser, Clark School assistant dean of strategic operations and IT. “You actually see the doctor’s face as opposed to being behind a big thing where you can’t see anything, which might be a better patient experience, too.”

Another approach—sterilizing used N95 masks—could quickly expand supply for clinicians. Clark School engineers are doing fast-tracked testing with doctors at local hospitals and researchers at the University of Maryland Baltimore.

They’re testing gamma radiation sterilization in the University of Maryland, College Park reactor facility to see if it can eliminate viruses and maintain the efficacy of filtration, Bentley said.

Current tests are aimed at finding out if gamma radiation—which could be done at a large scale commercially—degrades the mask in any way, he said.

Clark School bioengineers are also working to hack together simple, but functional ventilators. In hospitals overseas, doctors have faced wrenching life-and-death questions about which patients could be placed on the devices, which help people in respiratory distress breathe. And there are fears the United States could need hundreds of thousands more than it has on hand if COVID-19 spreads catastrophically.

"We’re working to find what are the real, critical aspects of the design that you can fashion together with standard materials, standard tubing,” Aroom said. “We’re taking a number of different approaches to that. We have the skill set here, both on the medical and engineering sides, to have a good potential for success.”

This story originally appeared on Maryland Today.

Published March 31, 2020